GO TO MARKET FASTER

3D Printing with PETG Filament

NE Print Shop

GO TO MARKET FASTER

NE Print Shop

Polyethylene terephthalate glycol (PETG) is among the primary 3D printing materials known for its excellent strength and ease of printing.

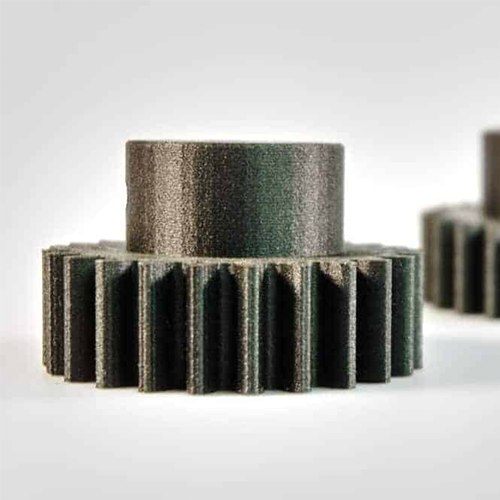

It is a modified version of PET plastic, and the addition of glycol lowers its melting temperature and enhances its chemical and impact resistance properties. It is recyclable, food-safe, and easy to print, making it a versatile 3D printing material. It is highly durable, and you can use PETG to create components such as end effectors, gears, and snap-fits parts, where strength is a significant criterion. PETG can be an excellent substitute for ABS as it is easy to print, easy to post-process, and offers better mechanical properties in comparison.

PET-G needs controlled printing conditions and slightly higher printing temperatures than PLA and ABS. You need an all-metal hot end and a heated bed to ensure good printing results with PETG.

It can be tricky to get an excellent first layer with PETG. It is prone to warping, and to avoid any print failures; you need to ensure that the first layer adheres to the bed flawlessly. A heated bed will help to minimize the temperature gradients and help PETG stick to the bed. If you’re using a glass bed surface, you can apply a thin layer of PVA glue stick or hairspray to achieve optimum first layer adhesion. Alternatively, you can also stick the Blue painters’ tape on the glass print bed.

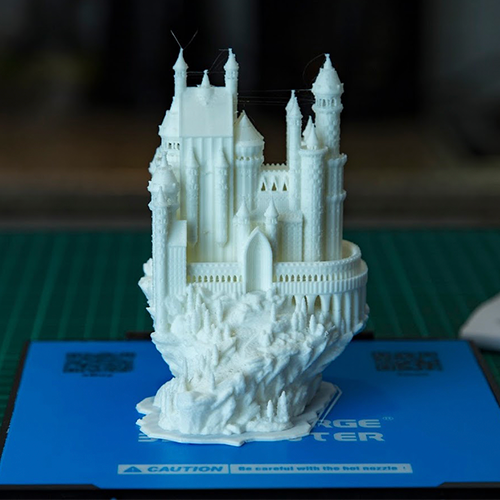

PETG is a sticky material and can cause issues related to retraction stringing. If you have incorrect settings, you’ll result in strings of filament all over your model. These affect the print quality and add an extra step in the post-processing stage. To prevent this, you need to calibrate and dial in your retraction settings. You can use the retraction settings for your particular roll of PETG filament.

If you print PETG at a high temperature, you might notice blobs or zits on your print’s surface, resulting in a poor surface finish and affecting your print quality. A high melting temperature will result in the PETG oozing out of the nozzle, leading to issues in print. A temperature tower will help you calibrate your extruder temperature and resolve any problems due to a high or low melting temperature.

PETG layers have excellent self-adhesion. While it might be nice in the case of the actual model, its self-adhesion might lead to specific issues in the case of the supports. The PETG might get stuck to the model, resulting in difficulties while removing the support material. You might find bits and pieces of support on the print and an unclean support interface. It is essential to tune the supports and adjust the ‘Z-height gap” setting. The settings should be such that the model’s support structure is easily detachable with minimal overhangs.

PETG is a hygroscopic material and will absorb moisture easily. You need to store the PETG filament roll in an air-tight storage container with desiccant in it. While printing, if you can print within an enclosure, it will minimize any chances of moisture in the filament.

PETG will adhere to the bed if you disable the part cooling fan for the initial few layers, and it will reduce any chances of warping and provide good bed adhesion for the further layers.

PETG filament is suitable for experienced 3D printer users. But, even as a beginner, you shouldn’t have any issues with using PETG in your projects. Here are some of the applications which benefit from PETG material.

PETG has high strength, durability, and better chemical resistance than ABS and PLA. It is easier to print than ABS while having better mechanical properties.

PETG filament has high tensile strength and elongation at break. You can find the exact details in the Material Safety Datasheet of your filament manufacturer. CNC kitchen also has a great video guide on PETG’s strengths.

Yes. PETG filament is a hygroscopic material and will absorb moisture easily.

You can use PETG to print snap-fit components, food-safe boxes, and objects which require a good chemical resistance. It can be used for printing flexible models too.

It is easily accessible, and you can buy it directly from Amazon or any other 3D printing material retailer.

PETG filament has good flexibility compared to PLA and ABS, and you can use it to print hinges and end-effectors.

You need to dry the PETG filament in an oven for half an hour at 65°C.

No. PETG filament is not toxic, but you need to ensure good ventilation when printing with PETG.

PETG filament can last for two years if stored properly, in an air-tight container, and away from sunlight.