GO TO MARKET FASTER

3D Printing with PLA Filament

NE Print Shop

GO TO MARKET FASTER

NE Print Shop

PolyLactic Acid – PLA filament is a starch-based thermoplastic that is one of the primary materials used in consumer-level 3D printing.

It is created by fermenting a carbohydrate source, mainly cornstarch in this case. As it is made up of cornstarch, PLA is also environmentally friendly and emits a sweet smell during the printing process. You can print PLA filament on even the most basic 3D printers without the need for any heated bed surface. And its inexpensive nature makes it suitable for a wide variety of applications ranging from models and toys to light load-bearing components.

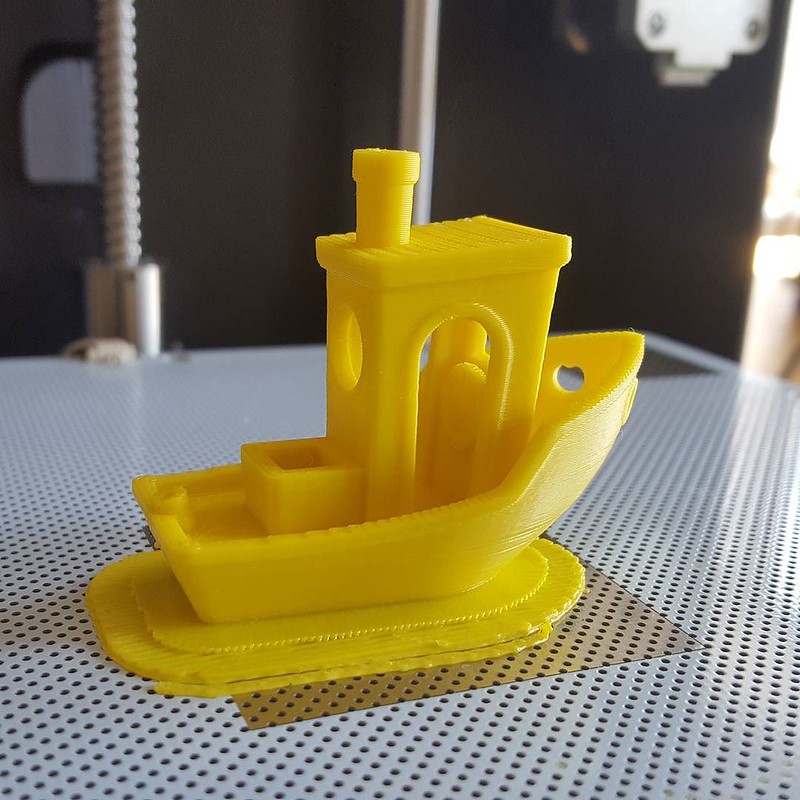

PLA is one of the most accessible materials to 3D print. And most consumer-level 3D printers can easily print PLA without any need for high-end components. Here are some of the recommended print settings for PLA:

PLA filament is a beginner’s material, and there is not much that you need to keep in mind while 3D printing it. Its easy-to-print nature is one of the main reasons many 3D printers are solely built for it. That being said, you can constantly improve your PLA print quality. Read on to learn more about the best practices to keep in mind while 3D printing with PLA.

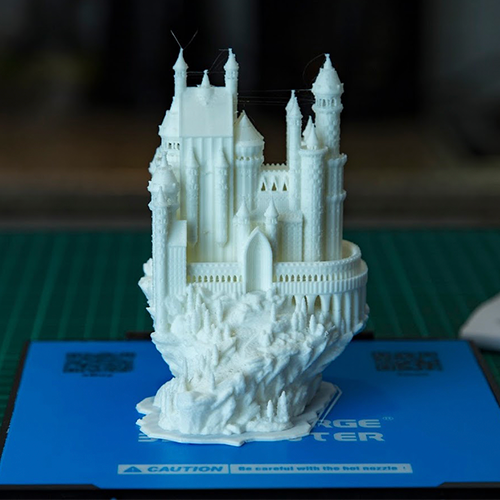

PLA 3D printing filament melts at lower temps and is an easy-flowing material. While it is excellent for ease of printing, this property can lead to PLA oozing from the nozzle. This oozing will result in hair or thin strings on your 3D print, and it makes the final result look messy and increases the post-processing times.

To prevent this, you need to fine-tune your retraction settings to reduce any excess PLA oozing from the nozzle. You can use temperature and retraction towers to tune these settings finely with every new 3D printing filament spool.

PLA filament likes to be cooled down as soon as it is extruded out of the nozzle, and it will result in better print quality and reduce any other artifacts that might occur on the print’s surface. This is why you will find that most of the PLA printers have an open-frame design or at least are partially enclosed, with the top being open.

While printing PLA, you need to keep the part cooling fan running at 100% for all the layers, except the first two. It will lead to better bed adhesion and excellent print quality.

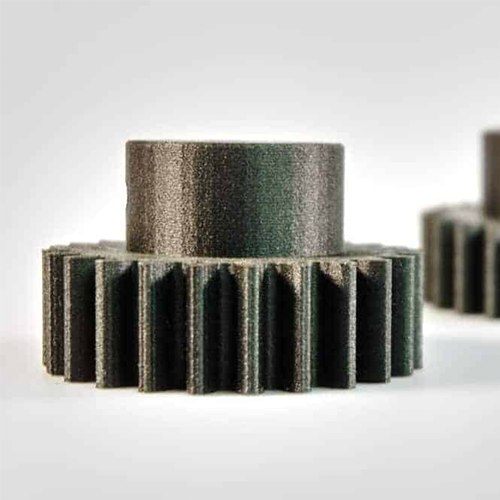

As stated earlier, PLA melts at low temps and flows easily. If you have a high extruder temperature, PLA might ooze out of the nozzle leading to stringing issues. On the other hand, a low temperature will lead to underextrusion problems. There are also many other varieties of PLA filament such as Wood PLA, Metal PLA, Carbon Fiber PLA, etc. These melt at different temperatures.

The optimal extruder range for PLA is between 190°- 210 °C. However, you need to check the filament manufacturer’s specifications to know the exact melting range for your particular PLA filament. A temperature tower will help you understand the precise melting temperature for your spool and benefit significantly in the long run.

PLA is not known for its post-processing ease, as it is comparatively stiffer than ABS, and you need lots of effort to get a high-quality result. However, just like acetone with ABS, you can use THF or Tetrahydrofuran to get a glossy surface on your PLA prints. You can even use PLA gloop to get a shining PLA model.

PLA is hygroscopic and will absorb the atmospheric moisture if left open in the air, and it will lead to print issues and air bubbles on your PLA model and even cause print failures. You need to store PLA filament in sealed bags or containers with desiccants and keep it away from sunlight.

PLA filament prints great in a well-ventilated space. Ensure that you have good air circulation and the part cooling fan is running at full speed.

If you’re printing with ABS and have a dual extruder printer, you can use PLA filament as support material as it does not adhere to ABS filament and will make removing supports easy.

Higher printing temperatures will give you better print results and a glossy surface finish. However, you need to ensure that the filament is not oozing at high temperatures.

PLA filament is for anyone a beginner in 3D printing or wants to experiment with the 3D printing process. Here are some of the applications and projects for PLA filament.

PLA is produced by fermenting the plant starch from corn and maize. The fermentation process turns the sugar in these starches into lactic acid, further used to create PLA.

PLA filament is suitable for printing small objects, minis, and display pieces. YOu can also use it for printing cosplay parts, swords, and small, functional parts.

PLA is best printed between 190°- 210 °C hot end temperature and a heated printing bed with 50°-60 °C. You need to turn ON the part cooling fan and run it at 100% speed.

You can dry PLA filament using a filament dryer or heat it in an oven at 50 °C for 20 – 30 minutes.

No. PLA filament is biodegradable and safe to 3D print, and does not emit any harmful 3D printing fumes.

While PLA is safe to use with food items, it is not safe to use after 3D printing it. The brass nozzle might induce impurities in the material, making it unsafe to use with any food items.

PLA filament can last between 5-10 years if stored under normal conditions.

PLA filament is not flexible and is instead brittle and hard. You cannot use it to print flexible items.